charpy impact test dimension|charpy impact chart : factories The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

WEBFilmes em cartaz no Cinema Espaço Itaú de Cinema - Cinema DF. Notícias; Estréias; Em Cartaz; Cinemas; Fale Conosco; Espaço Itaú de Cinema. Endereço: SGCV - Sul, Loja Ancora 3- A, 2 pavimento , Lote 22 - Guará - Brasília/DF. Telefone: (61) 3345-8669. Localização. Filmes. A Cor Púrpura. Anatomia de uma queda .

{plog:ftitle_list}

Nothing 是一家创新的科技公司,为您提供高品质的无线耳机和智能设备。在这里,您可以了解更多关于 Nothing 产品的信息,找到解决问题的方法,申请帮助和反馈意见。访问 Nothing 支持中心,探索使用方式,获取最新的系统更新,享受更好的听觉体验。

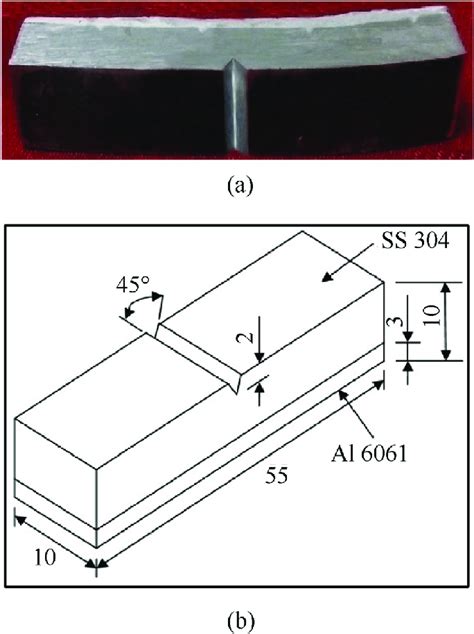

The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy .Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

shimadzu ag-is universal testing machine

(1) the sample by driving a. initiating at the notch. The sample geometry, with the notch facing away from the hammer’s. impact, is used to cause a stress concentration at the tip of the .Identify and measure the initial lateral dimensions of all specimens. Conduct impact tests on 5 as received 1018-steel and five aluminum (2024 or 6061) specimens heated or cooled to dry ice, .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .3.1.1 Impact tests are to be of the Charpy V-notch type. The test specimens are to be machined to the dimensions and tolerances given in Table 2.3.1 Dimensions and tolerances for Charpy .

Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: (a)To study the impact resistance of metals using impact testing machine of the Charpy type . Vernier calipers (to measure the dimensions of the specimen) (b)Theory Some materials like cast iron, glass and hard plastics o er considerable resistance to . Any test specimen preparation, conditioning, dimensions and testing parameters required by the materials specification sha. The store will not work correctly when cookies are disabled. All. All Meetings & Symposia Standardization . Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics D6110-18 ASTM .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3). Plastic deformation. Permanent deformation of the material when a load is applied, then removed.The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

3.2.2 Charpy V-notch impact tests may be carried out at ambient or lower temperatures in accordance with the specific requirements given in subsequent Chapters of these Rules. Where the test temperature is other than ambient, the temperature of the test specimen is to be controlled to within ±2°C for sufficient time to ensure uniformity throughout the cross-section of .Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values obtained can be used for quality control or to differentiate general toughness. Test Procedure:

The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3). Plastic deformation. Permanent deformation of the material when a load is applied, then removed.

(dimension J/m) or by the residual area under the notch (dimension kJ/m2). . The Charpy impact test has gained the greatest importance in the quality control in the last years because of its easily applicability, short testing time and low consumption of materials during the test. But, on the other side, itsThe standard Charpy Impact Test specimen consist of a bar of metal, or other material, 55x10x10mm having a notch machined across one of the larger dimensions. V-notch: 2mm deep, with 45° angle and 0.25mm radius along the base; U-notch and keyhole notch: 5mm deep notch with 1mm radius at base of notch; The Charpy Impact Test consist of striking .Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM standard E23 1, requiring a 55x10x10 mm beam with a 45°, 2 mm deep notch cut into the

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .ISO 13802:1999, Plastics Verification of pendulum impact-testing machines Charpy, Izod and tensile impact-testing. 3 Terms and definitions For the purposes of this part of ISO 179, the following terms and definitions apply. . direction of blow parallel to the dimension b, with impact on the narrow longitudinal surface h l of the specimen (see .The outer dimensions of specimens to ASTM D256 are specified to a length of 2.5 in (63.5 mm) and a height of 0.5 in (12.5 mm). The width of injection molded specimens may be between 0.118 in (3.0 mm) and 0.5 in (12.5 mm), whereby .

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen .Charpy specimens according ASTM E23-02a were manufactured. Figure 5 shows the dimensions of machined specimens. The toughness impact tests were carried out in a Rosand V1.01 machine (Rosand .Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces. This notch, which can be either V-shaped or U-shaped, is placed facing away from the pendulum and helps to concentrate the stress .

What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material’s notch toughness. The objective of the charpy impact test ?? To determine the material resistance to impact from a .

In order to develop the small specimen technology in Charpy impact testing, the effects of V-notch dimensions on the test results were investigated for miniaturized specimens of a ferritic steel, Japanese Ferrite/Martensite Dual Phase Steel (JFMS). The miniaturized Charpy specimens had four different square cross-sections of 3.3, 2, 1.5 and 1 mm, and each of them had a .This is a required test in the production of most of the steels described within the standard. Specimen dimensions are well-defined, and pictorial examples of the different failure types are included. For greater detail, ASTM A370 references the charpy impact standard ASTM E-23.

Class J Impact Testing System is widely used for lzod and Charpy impact test on plastics and rubber specimens. Equipped with tensile impact pendulum and fixtures, it can carry on tests on plastic film and sheet. The newly enhanced design offers the most cost-effective configuration to address Charpy test from 1J to 50J, and lzod test from 1J to .IS 1757 (1988): Method for charpy impact test (V notch) for metallic material [MTD 3: Mechanical Testing of Metals] IS : 1757 - 1908 . TABLE 2 TOLERANCES ON SPECIFIED TEST PIECE DIMENSIONS Derlgnatlon Nominal Mechlning Dimension Tolerance mm mm Length 55 f 0’60 Holght 10 f 0’06 Wldth: Standard test piece 10 f 0’11 . Determining the sample dimensions The sample shape required to perform a Charpy test is very simple. The samples are rectangular in size (measuring 127mm in legnth and 12.7mm in width) and have a nominal 12.7mm thickness. They feature a 45-degree V-notch with a 2.54mm notch radius. Mounting the specimen in the testing machineThe Charpy impact test is commonly used to assess plastics' toughness and impact resistance. It involves subjecting a standardized specimen to the impact of a swinging pendulum, causing a fracture. . The Class J - Charpy and Izod Automatic Impact Testing System has dimensions of 1000x300x760mm (Length x Width x Height). The machine's length .

ISO 13802, Plastics — Verification of pendulum impact-testing machines — Charpy, Izod and tensile impact-testing 3 Terms and definitions . direction of blow parallel to the dimension b, with impact on the narrow longitudinal surface h × l of the specimen Note 1 to entry: See Figure 1 a) and Figures 2 and 4. 3.4Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.

charpy test sample dimensions

Resultado da 20 de fev. de 2024 · The Poker Kings Club Is Play Money Only We Do Not Provide Or Promote Gambling Services. Memberships Are Very Limited – Act Now! BECOME A MEMBER : $50 USD. Pay For 12 Months ($50 USD) & Get 18 Months. *Bonus 6 Free Months – Limited Time Only*.

charpy impact test dimension|charpy impact chart